Now Available in a Low-Pressure Direct-Spark Model, Too!

The Most Innovative Concept in Heating

Performance Efficiency

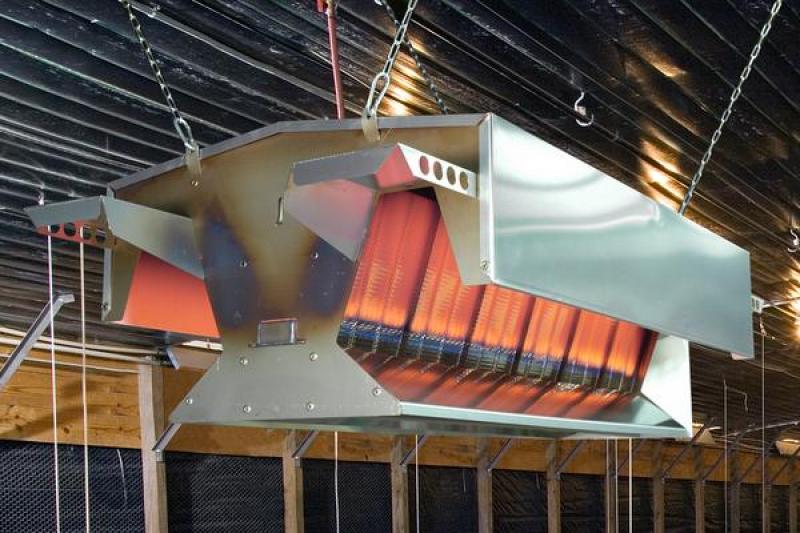

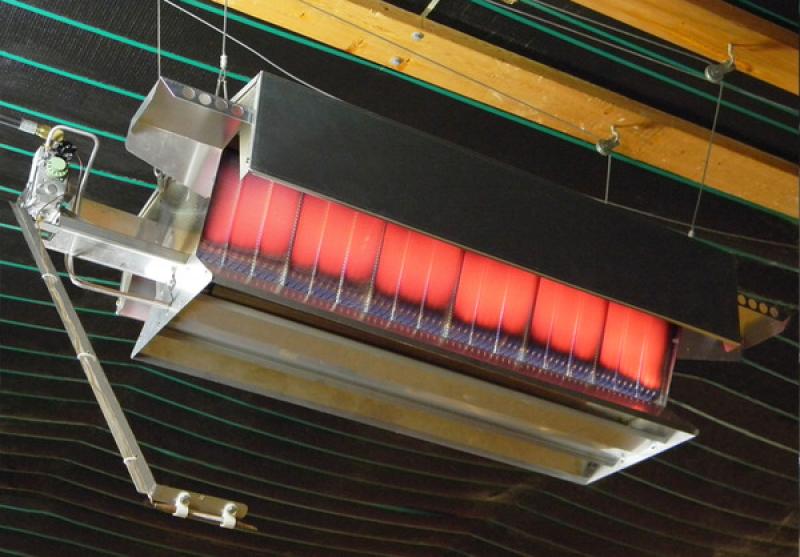

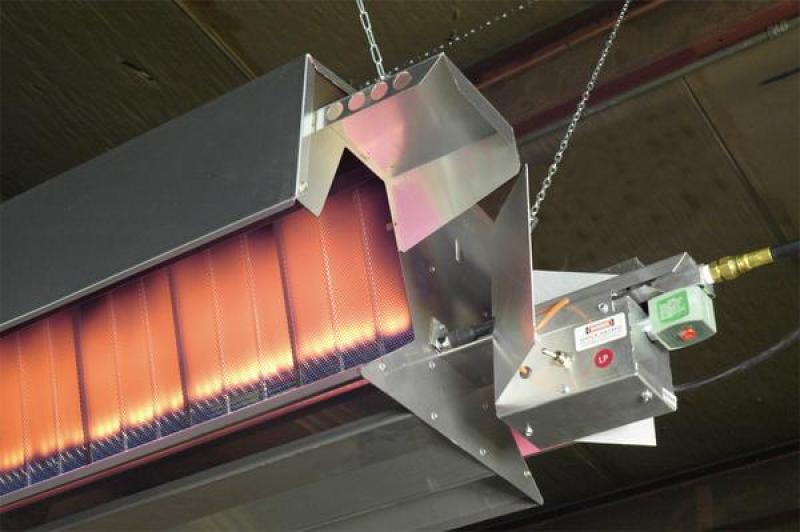

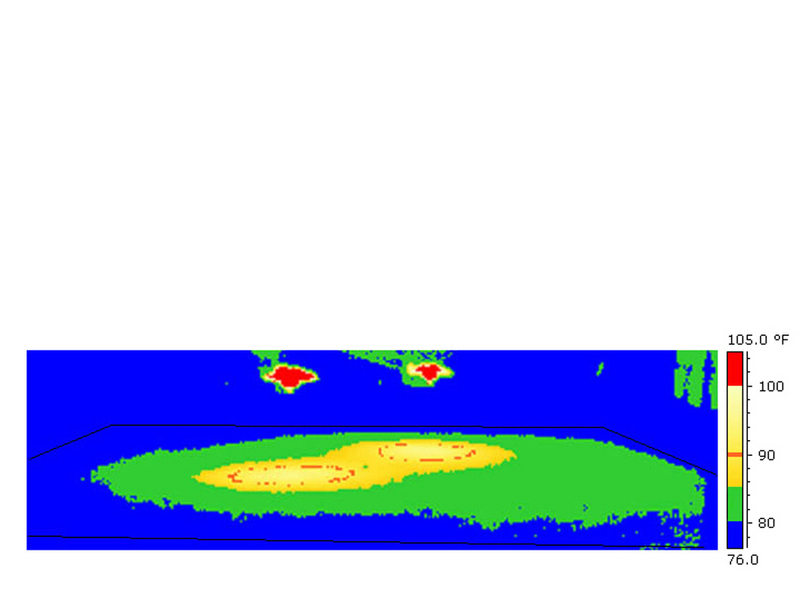

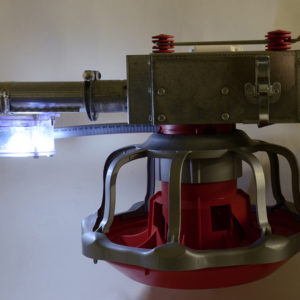

- The compact QUADRATHERM® Heater delivers a robust 80,000 BTUs of QuadRadiant® heat in a broad, quadrangular heat pattern.

- Uses fuel more efficiently by converting more of the thermal capacity of the gas to infrared heat and transferring more of that heat to the floor.

- Large, ribbed emitter surface area radiates more infrared heat than other heater styles.

- Unique shape and reflective surfaces enhance transfer of infrared heat to the floor.

- Spacious combustion chamber and highly effective burner enhance heater efficiency.

- Pressurized burner results in even heat distribution through all burner ports.

- Burner efficiency is further optimized using additional combustion air through the bottom of the heater.

- Adjustable height helps optimize floor coverage.

- QuadRadiant® heat requires less run time to heat a typical house.

- Saves fuel by permitting zone control – heat only the areas of the house where heat is needed.

Ease of Operation

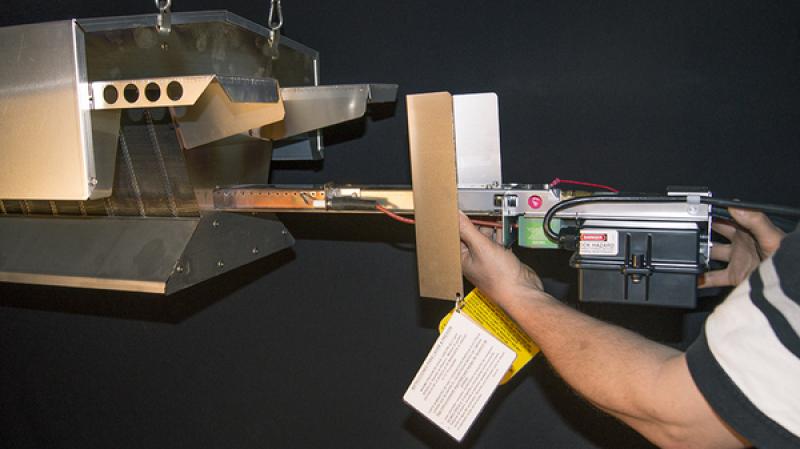

- Reliable direct spark ignition or 500-BTU pilot.

- Thermostatic, zone or individual sensor control.

- Proven, reliable component parts.

- Burner and igniter are protected from debris.

Delivered Assembled

- Heaters are delivered assembled and ready to hang.

- Units include 2.4-meter (eight-foot) power cords and gas hoses for flexible heater placement.

- 5-psi operation at the heater for high-pressure models reduces installation costs for piping and is retrofit friendly. (Low-pressure models require larger piping.)

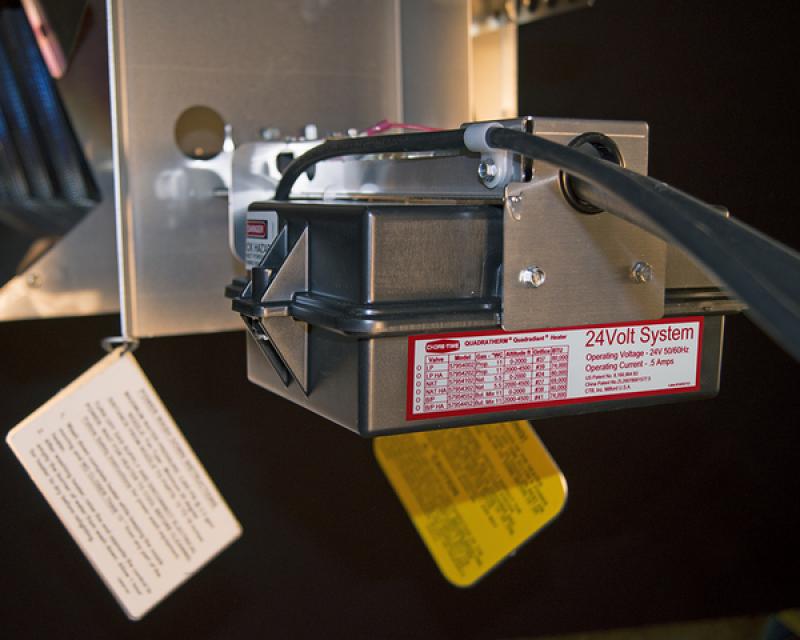

- 120-volt zone control model does not require a transformer. (24-volt requires a transformer but also permits battery back-up, except for direct spark model.)

- Slotted tabs at the corners of the heater permit secure four-point suspension for extra stability.

Easy Access for Maintenance

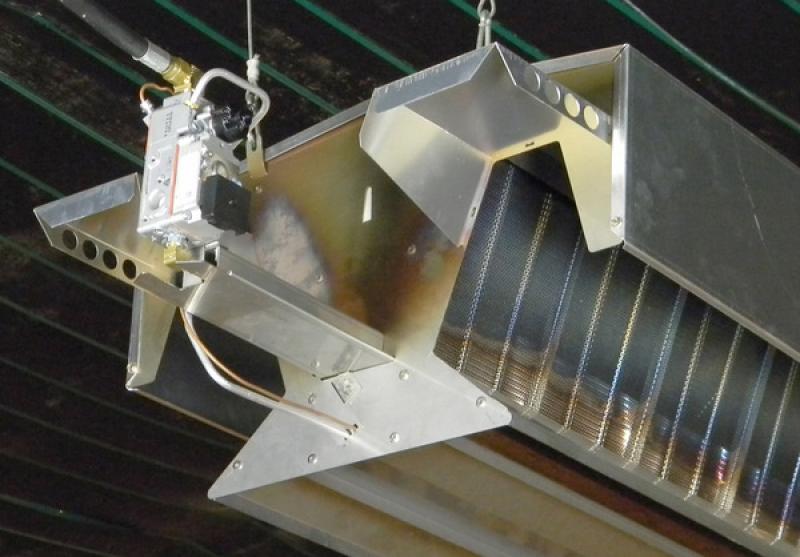

- Burner is easy to access by removing one screw.

- Three-piece bottom eases access for cleaning.

- Corrosion-resistant stainless steel and aluminum construction. Designed for compressed air cleaning.

- Heaters are winchable for house clean-out.

Controls Sealed from Debris and Water

- Dust-Tight (DT) – Dust-Tight, high-temperature, co-polymer enclosures are standard on all control systems to protect against dust, dirt, and moisture. The Dust- Tight enclosure also facilitates access to interior components.

- Wash-Down-Proof (WDP) – A Wash-Down-Proof option features the same high-temperature, co-polymer enclosure plus sealed components and a gasketed housing that prevents water penetration. This permits power washing, if required for biosecurity.

- Both enclosures have high dielectric strength and include fireretardant properties to resist the spread of flames.

Advantages vs. Tube Heat

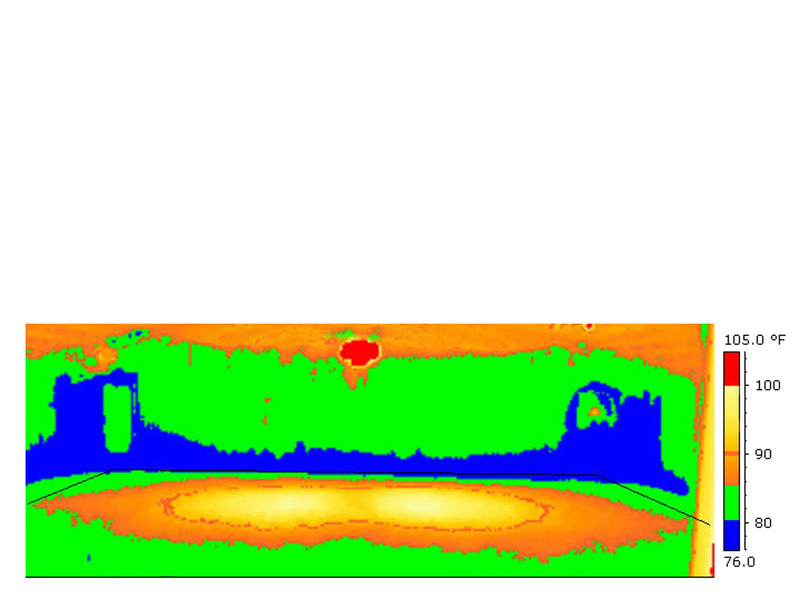

- More even heat pattern.

- More efficient conversion of fuel to heat.

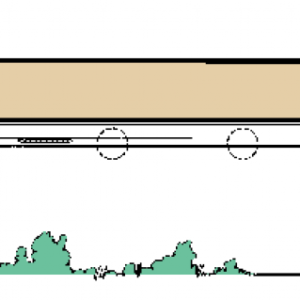

- Rectangular heat profile matches the shape of a poultry house.

- Flexible for various house widths – no need for various models to get good, even heat.

- Winchable for easy access for service.

- Quicker up to temperature.

- No problematic air intakes or ducting.

- Units are easy to move.

- Low-pressure, snap-action model runs without electricity.

Advantages vs. Brooders

- Requires fewer units – perhaps as few as one QuadRadiant® Unit to replace two infrared brooders or four convection brooders, depending on house configuration.

- More even heat pattern.

- More efficient conversion of fuel to heat.

- Rectangular heat profile matches the shape of a poultry house.

- Quicker up to temperature.

QuadRadiant® Heat Solves Typical Heating System Problems

- Rectangular, house-shaped heat patterns from QuadRadiant® Heaters are even and match the rectangular shape of a poultry house.

- A single QuadRadiant® Model provides broad, even heat for most house widths.

- With the QuadRadiant® Heater, more even heat patterns result in a larger comfort zone for birds and save fuel (hot spots waste fuel.)

- QuadRadiant® Heaters are winchable for easy access for service and maintenance, and they are designed for simplified maintenance.

- Installing QuadRadiant® Heaters requires no problematic air intakes, ducting or pressurized combustion.